Expansion Joints: A Solution for Displacement, Vibration, and Corrosion in Piping Systems

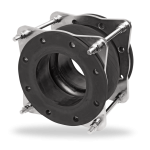

Expansion Joints, also known as Expansion Couplings, are used to address displacement, vibration, oscillation, corrosion, and other issues caused by temperature changes and various fluids in ducts and pipes. These joints are designed to dissipate thermal expansion and contraction, resist high temperatures and pressures, and withstand corrosive fluids.

Types of Expansion Joints

- Metal Expansion Joints: Suitable for high temperatures and pressures, and corrosive fluids.

- Rubber Expansion Joints: Suitable for greater flexibility and absorption of vibration and noise.

- Fabric Expansion Joints: Suitable for high temperatures and pressures, and corrosive fluids, while maintaining good flexibility.

Design and Manufacturing The design of expansion joints and the selection of materials used in them are based on technical specifications such as the type of passing fluid, internal temperature and pressure of ducts, fluid corrosiveness, etc. This is done by Klevers Aryana’s technical and engineering unit based on customer requirements.

Klevers Aryana Company

- Started its activities in 2001 focusing on fabric expansion joints.

- Initially collaborated with Seiris Company of France in transferring knowledge and technology related to the construction of these joints.

- Currently one of the main manufacturers of rubber, metal, and fabric expansion joints in Iran.

Advantages of Using Klevers Aryana Expansion Joints

- Increased lifespan of piping systems

- Reduced maintenance and repair costs

- Improved system safety and efficiency

- Variety in material and model

- High quality

- Reasonable price

For more information and free consultation, contact Klevers Aryana experts.