اتصالات انبساطی (اکسپنشن جوینت): راه حلی برای جابجایی، لرزش و خوردگی در سیستمهای لولهکشی

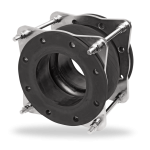

اتصالات انبساطی که به اکسپنشن جوینت نیز معروف هستند، برای جابجایی، لرزش، نوسان، خوردگی و سایر مشکلات ناشی از تغییرات دمایی و سیالات مختلف در مسیر داکتها و لولهها به کار میروند. این اتصالات برای دفع انبساط و انقباض حرارتی، مقاومت در برابر دما و فشارهای بالا و سیالات خورنده طراحی شدهاند.

انواع اتصالات انبساطی

- اتصالات انبساطی فلزی: برای دما و فشارهای بالا و سیالات خورنده مناسب هستند.

- اتصالات انبساطی لاستیکی: برای انعطافپذیری بیشتر و جذب لرزش و صدا مناسب هستند.

- اتصالات انبساطی پارچهای: برای دما و فشارهای بالا و سیالات خورنده مناسب هستند و در عین حال انعطافپذیری خوبی دارند.

طراحی و ساخت

طراحی اتصالات انبساطی و انتخاب نوع متریال مصرفی در آنها بر اساس مشخصات فنی مانند نوع سیال عبوری، دما و فشار داخلی داکتها، میزان خورندگی سیال و … توسط واحد فنی و مهندسی کلورز آریانا و بر اساس درخواست مشتریان صورت میگیرد.

شرکت کلورز آریانا

- فعالیت خود را از سال 1380 با تمرکز بر اتصالات انبساطی پارچهای آغاز نموده است.

- در ابتدا با کمپانی Seiris فرانسه در انتقال دانش و فن مرتبط با ساخت این اتصالات همکاری میکرده است.

- در حال حاضر از تولیدکنندگان اصلی اتصالات انبساطی لاستیکی، فلزی و پارچهای در ایران میباشد.

مزایای استفاده از اتصالات انبساطی کلورز آریانا

- افزایش طول عمر سیستمهای لولهکشی

- کاهش هزینههای تعمیرات و نگهداری

- افزایش ایمنی و راندمان سیستم

- تنوع در جنس و مدل

- کیفیت بالا

- قیمت مناسب

برای کسب اطلاعات بیشتر و دریافت مشاوره رایگان با کارشناسان کلورز آریانا تماس بگیرید.