In high-temperature industrial systems, ducts and piping are not rigid, immobile structures. Thermal expansion, vibrations from fans and pumps, and minor installation misalignments exert enormous forces on the system, which, if not managed, can lead to cracks, fractures, and catastrophic production line shutdowns. The design and engineering of fabric spring joints, more commonly known in the industry as Spring Joints, is the advanced engineering solution to this challenge.

These flexible systems not only accommodate multi-axial movements but also act as effective thermal and acoustic insulators, ensuring the integrity of hot gas transport systems. In this article, we will dissect the complex process of designing and engineering these critical components.

What is a Fabric Spring Joint and Why is it Vital?

A fabric spring joint is a flexible, composite connection designed to create a continuous seal between two ducts or pieces of equipment that move relative to each other. Their critical importance is summarized in three main functions:

- Accommodating Movements: Absorbing thermal expansion and contraction (axial), lateral displacements, and angular movements.

- Isolating Vibrations: Preventing the transmission of vibrations from mechanical equipment (like fans) to other parts of the system.

- Compensating for Misalignment: Correcting for minor errors in duct alignment during installation.

Using rigid connections instead of these systems is like intentionally creating a weak point in the system that will sooner or later lead to failure.

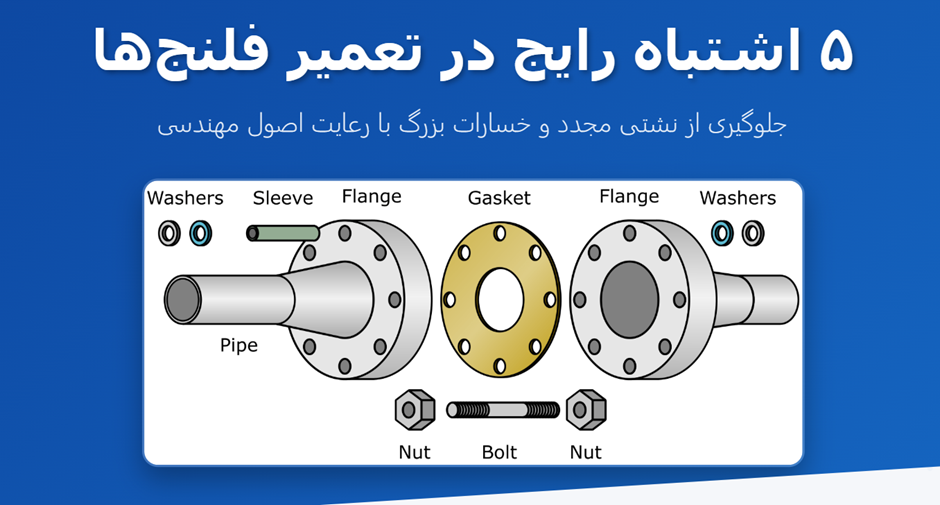

Anatomy of a Fabric Expansion Joint

A fabric spring joint system is not just a piece of refractory fabric, but an engineered, multi-layered assembly where each component has a specific function:

- Composite Fabric Belt: This is the main component that provides the seal. Depending on the temperature and chemical conditions, this layer can be composed of several different fabrics such as silicone-coated fiberglass, vermiculite-coated silica fabric, or PTFE fabric for chemical resistance.

- Insulation Bolster: A thick cushion placed inside the joint, responsible for the primary thermal insulation. This part is usually made of a high-density ceramic blanket or rock wool to prevent temperature drop and heat from reaching the outer layers.

- Metal Frame: This component serves as the interface between the fabric joint and the metal ducts. Its design is crucial for uniform force distribution and ensuring a complete seal.

- Baffle/Flow Liner: An internal metal plate that protects the fabric layers from the direct flow of abrasive, high-velocity gases, significantly increasing the system’s service life.

The Design and Engineering Process: From Needs Assessment to Manufacturing

Designing a fabric expansion joint is a precise engineering process that requires an analysis of the operational conditions.

Step 1: Detailed Analysis of Operating Conditions

The first and most important step is to gather accurate data from the installation site:

- Temperature: Minimum, maximum, and continuous operating temperature.

- Pressure: Positive, negative (suction), or fluctuating pressure.

- Gas Composition: Identification of corrosive gases such as sulfur compounds or acids.

- Extent of Movements: Precise measurement of the expected axial, lateral, and angular displacements.

- Flow Velocity and Type: Presence of abrasive particles in the gas stream (such as ash or catalyst).

Step 2: Engineered Material Selection

Based on the data from the previous step, engineers select the appropriate materials for each layer. For example:

- For temperatures up to 550°C, silicone-coated fiberglass fabric is an economical and efficient choice.

- For temperatures approaching 1000°C, silica-based or ceramic fiber fabrics are necessary.

- In highly acidic environments, the use of PTFE (Teflon) layers for chemical protection is mandatory.

Standards such as ASTM F1123 provide useful guidelines on the specifications for these types of joints.

Step 3: Mechanical and Thermal Design

In this stage, engineers use CAD and Finite Element Analysis (FEA) software to design and calculate the following:

- Joint Geometry: Determining the precise dimensions and overall form for optimal movement absorption.

- Metal Frame Design: Calculating the plate thickness and connection type to the duct to withstand compressive and tensile loads.

- Thermal Calculations: Ensuring that the external surface temperature of the joint remains within a safe range and preventing the formation of an Acid Dew Point inside the bolster.

Klevers Aryana: Your Specialist in Designing and Manufacturing Flexible Connections

Designing and manufacturing a fabric spring joint that can endure years of harsh industrial conditions requires a combination of engineering knowledge, practical experience, and access to high-quality raw materials. Klevers Aryana Company, relying on years of experience in thermal solutions, brings this expertise to the heart of Iran’s industry.

At Klevers Aryana, we offer comprehensive solutions in this field:

- Specialized Product: We are proud to design and manufacture Fabric Spring Joints as one of our key products, with the highest quality and tailored to the specific needs of each industry.

- Engineering Services: Our engineering team will visit your project site, collect all operational data, and design a fully customized solution based on it. These engineering services guarantee that the final product is exactly what you need.

- Complete Product Portfolio: In addition to spring joints, we offer a wide range of insulation and refractory products to complete your thermal system.

If you are facing challenges from thermal expansion and vibrations in your ducting systems, consult with our experts today through our Contact Us page and receive a durable, engineered solution.

References:

- Expansion Joint Manufacturers Association, Inc. (EJMA), “Standards of the Expansion Joint Manufacturers Association.”

- U.S. Bellows, Inc., “Fabric Expansion Joints Design,” usbellows.com.

- EagleBurgmann, “Expansion joints: Design and function,” eagleburgmann.com.

- Process Barron, “The Complete Guide to Fabric Expansion Joints,” processbarron.com.

- International Organization for Standardization (ISO), Standards for flexible piping components.