Turbine insulators play a vital role in the optimal performance, safety, and energy efficiency of turbine systems. However, many engineers and industry professionals overlook the importance of regular inspections and proper maintenance of turbine insulators. In this comprehensive article, we will examine the principles, methods, and best practices for maintaining and periodically inspecting turbine insulation to ensure your systems operate with maximum efficiency and safety.

Importance of Maintenance and Periodic Inspection of Turbine Insulation

Turbine insulators are exposed to harsh operating conditions. High temperatures, continuous vibrations, temperature fluctuations, and environmental contaminants can all cause gradual deterioration and damage to the insulation system over time. Regular and periodic inspections not only help identify problems early but also offer numerous benefits:

- Increased Safety: Damaged insulators can pose serious safety hazards such as personnel burns, fire, or release of hazardous materials.

- Improved Performance: Healthy and efficient insulation helps maintain optimal temperatures and prevents heat loss.

- Cost Savings: Timely detection and resolution of minor issues prevents them from becoming expensive failures.

- Extended Equipment Life: Proper insulation protects sensitive turbine components and increases their service life.

- Reduced Downtime: A regular maintenance schedule allows repairs to be performed during planned outages and prevents emergency shutdowns.

Types of Turbine Insulation and Maintenance Challenges

Before discussing inspection protocols, it’s important to understand the main types of insulation used in turbines:

1. Removable Jacket Insulation

Jacket insulation is among the most popular options for turbines because they can be removed and reinstalled for maintenance and periodic inspections. These insulations usually consist of multiple layers:

- Weather-resistant outer layer (usually silicone fiberglass fabrics)

- Insulating middle layer (fiberglass felt or microporous materials)

- Heat-resistant inner layer

Maintenance Challenges: Damage to fasteners (hooks, straps), tearing of the outer cover, compression of insulation materials, and improper installation after inspections.

2. Traditional Fixed Insulation

This type of insulation is installed directly on the turbine surface and usually consists of mineral wool, fiberglass, or ceramic materials protected by a metal covering.

Maintenance Challenges: Difficulty of inspection without destruction, moisture accumulation, corrosion under insulation, and high replacement costs.

3. Advanced Ceramic Insulation

For high-temperature applications, advanced ceramic insulation is used due to its ability to withstand extremely high temperatures.

Maintenance Challenges: Brittleness, impact sensitivity, and high repair costs.

Periodic Inspection Protocols for Turbine Insulation

A comprehensive inspection program should include regular checks at specified intervals. Below is a standard inspection schedule:

Daily/Weekly Quick Visual Inspections

These inspections are performed by frontline operators or technicians:

- Check for any visible damage to the insulation outer cover

- Identify steam or fluid leaks from insulation joints

- Inspect loose connections and fasteners

- Record unusual hot spots (using handheld thermal camera if possible)

Monthly/Seasonal Inspections

These inspections are performed by maintenance technicians:

- Comprehensive Thermal Inspection: Use of thermographic cameras to identify hot spots that indicate insulation defects

- Moisture Check: Use of moisture meters to detect water infiltration in insulation

- Connection Inspection: Strength testing of all connections, hooks, and straps

- Joints Inspection: Ensure tightness and no leakage at insulation component connections

- Outer Cover Inspection: Identify tears, abrasion, or other damage

Annual/Major Repairs Inspections

During scheduled shutdowns or major repairs:

- Complete Inspection with Removal of Insulation: Removing removable insulation to examine the underlying surface

- Under Insulation Corrosion Inspection: Using non-destructive methods such as PEC Testing to identify corrosion under insulation

- Insulation Material Quality Test: Examining material compression, degradation, or contamination

- Support Systems Inspection: Testing pins, brackets, and other insulation support components

- Thermal Performance Evaluation: Measuring insulation thermal performance with specialized instruments

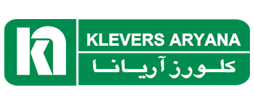

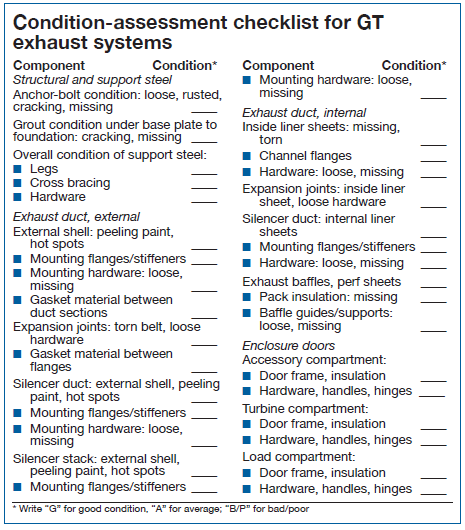

Comprehensive Turbine Insulation Inspection Checklist

To ensure complete and accurate inspections, use the following checklist:

1. Visual Condition Inspection

- □ The outer cover is intact (no tears, holes, or abrasion)

- □ The insulation color is normal (no discoloration from heat or contamination)

- □ Connections and fasteners are secure

- □ Joints and overlaps are complete with no gaps

- □ There are no signs of liquid or steam leakage

2. Thermal Performance Inspection

- □ The external surface temperature of the insulation is within design limits

- □ No abnormal hot spots exist

- □ The temperature gradient is uniform

- □ The ambient temperature around the turbine is within acceptable limits

3. Support Systems Inspection

- □ Pins and brackets are intact and free from corrosion

- □ Welds of support connections are intact

- □ Distance between supports complies with design specifications

- □ Metal insulation support components are free from cracks or deformation

4. Insulation Materials Inspection

- □ Insulation materials are not compressed or crushed

- □ No contamination or foreign materials in the insulation

- □ Moisture has not penetrated the insulation

- □ Insulation materials are not damaged (no brittleness or crumbling)

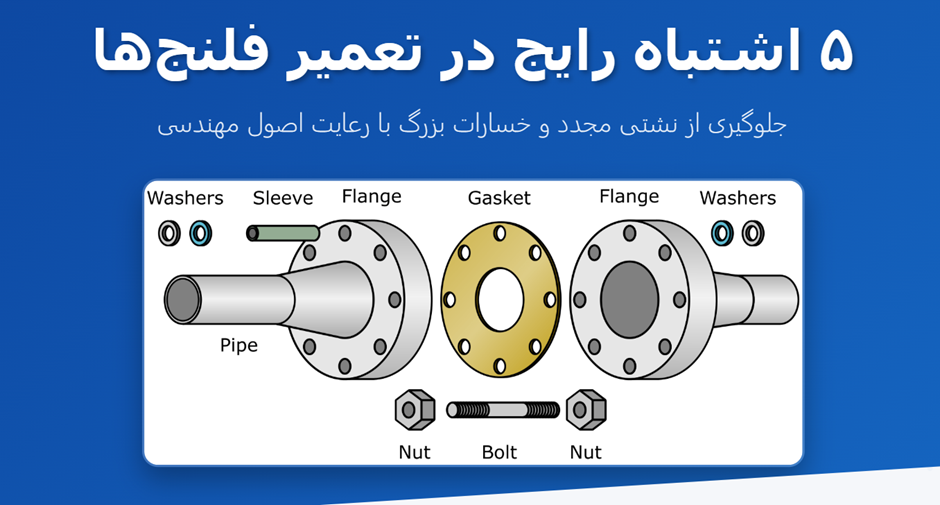

5. Special Points Inspection

- □ Insulation around connections and flanges is intact

- □ Insulation around inspection ports and sensors is undamaged

- □ Insulation at pipe and cable penetrations is continuous

- □ Intersections with other systems have no issues

Advanced Techniques for Turbine Insulation Maintenance and Inspection

New technologies provide the capability for more precise and non-destructive insulation inspections:

1. Infrared Thermography

Advanced thermal cameras can identify abnormal temperature patterns that indicate insulation defects. This method is non-contact and can be performed while the turbine is in operation.

Key Tips:

- Conduct inspections under stable load conditions

- Capture images from various angles

- Compare results with previous data

- Temperature differences exceeding 10°C compared to similar areas require further investigation

2. Pulsed Eddy Current (PEC) Testing

This method is used to identify corrosion under insulation without needing to remove the insulation. Electromagnetic signals pass through the insulation and determine the condition of the underlying metal.

Advantages:

- No need for direct contact with the metal surface

- Ability to inspect through insulation up to 152 mm thick

- Capability to detect corrosion, erosion, and cracks under insulation

3. Ultrasonic Testing

High-frequency sound waves can be used to measure insulation material thickness and identify inhomogeneities.

Applications:

- Determining actual insulation thickness

- Identifying compressed areas

- Detecting voids and empty spaces in insulation

4. Online Monitoring Systems

Temperature, moisture, and vibration sensors installed at strategic points can provide real-time data about the insulation condition.

Advantages:

- Early warning when a problem occurs

- Recording trends of changes over time

- Reducing the need for frequent physical inspections

Preventative Maintenance of Turbine Insulation

Proper maintenance can significantly extend the life of insulation:

1. Periodic Replacement Program

Even the best insulations eventually need replacement. Develop a periodic replacement program based on the expected service life of the insulation:

- Standard Removable Jacket Insulation: Every 5-7 years or after 3-5 opening and closing cycles

- Advanced Ceramic Insulation: Every 8-10 years

- Traditional Fixed Insulation: Every 7-10 years

2. Immediate Repair of Minor Damages

Repair minor damages immediately before they spread:

- Repair small tears in the outer cover with special patches

- Tighten loose connections and fasteners

- Re-seal open joints

3. Protection Against Environmental Conditions

- Prevent water and moisture from penetrating the insulation

- In corrosive environments, use corrosion-resistant coatings

- In high-vibration areas, use anti-vibration systems

4. Staff Training

- Train maintenance technicians on proper installation and inspection of insulation

- Prepare clear instructions for removing and reinstalling insulation

- Educate on the importance of promptly reporting any visible damage

Documentation and Data Management of Inspection

An accurate documentation system is essential for tracking the condition of insulation over time:

1. Creating an Identity Card for Each Insulation Section

- Unique identification number

- Installation date

- Technical specifications (type, thickness, materials)

- Manufacturer and model

- Precise installation location

2. Recording Inspection History

- Date of each inspection

- Type of inspection performed

- Findings and observations

- Actions taken

- Name of inspector

3. Trend Analysis

- Compare inspection results over time

- Identify recurring problem patterns

- Predict repair and replacement needs

4. Use of Computerized Maintenance Management System (CMMS) Software

CMMS systems can be very useful in managing turbine insulation maintenance and inspection programs:

- Automatic scheduling of inspections

- Repair and replacement alerts

- Storage of images and inspection reports

- Analysis of maintenance costs

Safety Guidelines for Turbine Insulation Inspection and Maintenance

Safety must always be a priority:

1. Thermal Hazards

- Always use appropriate personal protective equipment

- Allow the system to cool sufficiently before opening the insulation

- Use heat-resistant gloves

2. Respiratory Hazards

- When working with fibrous insulation materials, use appropriate respiratory masks

- In enclosed spaces, ensure adequate ventilation

- Use wet methods to reduce dust

3. Chemical Hazards

- Become familiar with the materials used in insulation

- Read the Material Safety Data Sheets (MSDS)

- Use appropriate gloves and eye protection

4. Working at Heights

- Use fall protection equipment

- Inspect scaffolding and work platforms

- Follow safe access methods

Case Studies: Lessons from Real Experiences

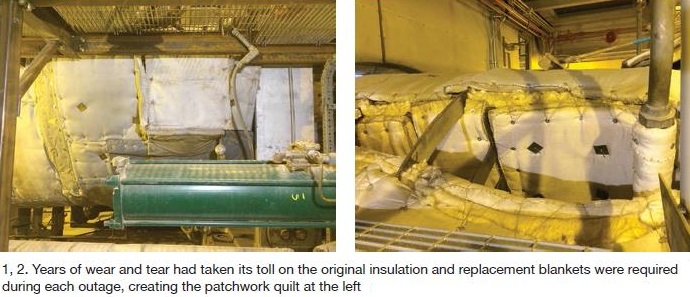

Case 1: Combined Cycle Power Plant

A combined cycle power plant with a 501F gas turbine encountered various problems with its insulation system after 10 years of operation. Inspections showed that about 15% of the insulation needed replacement during each major overhaul. The main problems included:

- Damage to insulation caused by repeated opening and closing cycles

- Accumulation of contamination between the insulation and turbine body

- Loosening of retaining pins

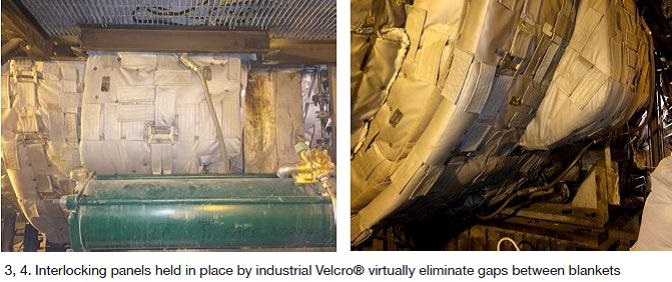

Solution: The power plant decided to completely replace the insulation system with a more advanced system featuring:

- Variable thickness to maintain uniform temperature

- Locking panels to eliminate gaps

- An improved connection system using bolts and nuts instead of pins

Results: After installing the new system, the time required to open the insulation was halved, and the turbine chamber temperature decreased significantly.

Case 2: Oil Refinery

An oil refinery faced corrosion under insulation in its steam turbines. Investigations showed that moisture penetration into the insulation over the years had caused severe corrosion.

Solution: The refinery implemented a periodic inspection program using PEC technology to identify corrosion under insulation without needing to remove the insulation.

Results: During the first year of the program, several cases of severe corrosion were identified and repaired before leaks or failures occurred.

Optimizing Turbine Insulation Maintenance Costs

Managing turbine insulation maintenance costs is an important challenge. The following strategies can help optimize costs:

1. Life Cycle Cost (LCC) Analysis

Rather than focusing on initial cost, consider the total life cycle costs:

- Purchase and installation costs

- Maintenance and repair costs

- Energy costs (due to heat loss)

- Replacement costs

- Disposal costs

2. Use of High-Quality Insulation

Inexpensive insulation may seem cost-effective in the short term but can lead to higher costs in the long run:

- Need for premature replacement

- Higher energy losses

- More downtime for repairs

3. Optimization of Inspection Program

- Prioritize preventive inspections based on risk and importance of each section

- Use non-destructive techniques to reduce the need to open insulation

- Coordinate inspections with shutdown schedules

4. Standardization of Insulation Systems

Standardizing the types of insulation used can have the following benefits:

- Reduced spare parts inventory

- Easier staff training

- Improved installation and repair quality

Future of Turbine Insulation and Inspection Technologies

The insulation and inspection industry for turbines is undergoing transformation. Future trends include:

1. Advanced Insulation Materials

- Aerogel Insulation: With extremely low thermal conductivity and resistance to moisture

- Nanocomposite Insulation: With improved mechanical and thermal properties

- Smart Insulation: With properties that change in response to environmental conditions

2. Advanced Inspection Technologies

- Thermal Camera Equipped Drones: For inspecting difficult-to-reach areas

- Smart Sensors: For continuous monitoring of insulation status

- Artificial Intelligence: For analyzing inspection data and predicting failures

3. Advanced Data Management Systems

- Digital Twins: Three-dimensional digital models of insulation systems for simulation and prediction

- Augmented Reality: To assist technicians with inspection and repair

- Integration with Asset Management Systems: For optimizing maintenance decisions

Conclusion

Periodic maintenance and inspection of turbine insulation is a critical aspect of industrial asset management that is often overlooked. By implementing a comprehensive inspection program, using advanced techniques, and following best maintenance practices, you can:

- Increase system safety

- Improve turbine performance

- Reduce maintenance costs

- Extend equipment life

- Prevent unplanned shutdowns

Remember that a healthy insulation system not only contributes to greater productivity but also provides a safer environment for employees and reduces energy consumption.

Introduction to Klevers Aryana Company

Klevers Aryana Company is one of the pioneers in the production and supply of various industrial and thermal insulation products in Iran. With years of experience in insulating industrial equipment, this company provides comprehensive and specialized solutions for various industries including power plants, refineries, and petrochemical industries.

Klevers Aryana’s turbine insulation products include:

- Removable thermal jacket insulation with separation and reinstallation capabilities

- Valve thermal jacket insulation for industrial valves

- Variety of high-temperature resistant thermal insulation materials

- Custom insulation systems for gas and steam turbines

In addition to supplying high-quality products, Klevers Aryana provides consulting, design, installation, and maintenance services for insulation systems. The company’s expert specialists can assist you in optimizing turbine insulation systems and developing inspection and maintenance programs.

For more information about Klevers Aryana’s products and services and to receive specialized consultation, please visit our Contact Us page.

Resources and References

- Combined Cycle Journal – Insulation Systems

- Allied Power Group – Best Practices for Turbine Shaft Inspection

- MaintWiz – Preventive Maintenance for Turbines: A Comprehensive Guide

- [IRSA Inspection – Under Insulation and Concrete Corrosion Inspection Using PEC Method]