In the world of engineering and industrial maintenance, creating a durable bond between components has always been a major challenge. When it comes to resisting mechanical stress, corrosive chemicals, and especially extremely high temperatures, conventional single-component adhesives lose their effectiveness. This is where the Two-Component Adhesive enters the scene as the champion of industrial bonding agents.

Contrary to the common belief that these adhesives are only for household use (like twin-tube glues), in industries such as petrochemicals, steel, and induction furnaces, engineered two-component adhesives play a vital role in sealing and repairing valves, pipes, casings, shafts, and more. In this article from Klevers Aryana, we will delve into the mechanism, types, and applications of this powerful material.

What Exactly is a Two-Component Adhesive and How Does It Work?

A two-component adhesive, as its name suggests, consists of two separate parts that have no adhesive properties on their own. However, as soon as they are mixed, they undergo an exothermic chemical reaction. These two parts are typically:

- Resin: The main polymer base.

- Hardener: The agent that initiates the polymerization reaction.

When these two components are mixed in a specific ratio, a process called Cross-linking occurs. According to the ASTM D1002 standard, which measures the shear strength of adhesives, this network structure makes the final bond much tougher, more resistant, and more stable than single-component adhesives (which cure by solvent evaporation).

Key Advantages of Industrial Two-Component Adhesives:

- Curing without Air: Suitable for enclosed environments and unventilated spaces.

- Outstanding Mechanical Resistance: Withstands high pressure and tension.

- Chemical Stability: Resistant to acids, bases, and solvents.

Introducing a Specialty Two-Component Adhesive: Klevers 101 Paste

If you are looking for a product that performs beyond conventional two-component adhesives, Klevers Aryana recommends Klevers 101 Paste.

This product is a sealing paste and high-temperature adhesive specifically formulated for harsh industrial conditions. Although its mechanism of action may differ from traditional epoxies, its performance as a powerful bonding agent in insulation systems is unparalleled.

Outstanding Features of Klevers 101 Paste

- High Thermal Resistance: Stable at temperatures where conventional adhesives would turn to dust.

- Excellent Adhesion: Securely bonds refractory fibers, ceramic ropes, and packings to metal and furnace surfaces.

- Asbestos-Free: Completely safe and compliant with European environmental standards.

- Easy to Use: Adjusted viscosity for easy application on vertical surfaces without sagging.

View Technical Specifications and Purchase Klevers 101 Paste

Technical Comparison Table: Conventional Two-Component Adhesive vs. Klevers 101 Engineering Adhesive

In industry, the difference between a temporary fix and a permanent repair lies in the technical details. The following table shows the stark difference between general-purpose epoxy adhesives on the market and the Klevers 101 Two-Component Adhesive (a joint product with technology from Resimac, UK):

| Feature | Conventional Two-Component Adhesive (General Purpose) | Klevers 101 Engineering Repair Adhesive |

| Chemical Nature | Solvent-based epoxy | 100% Solids, Solvent-Free Epoxy |

| Compressive Strength | Approx. 3000 to 5000 psi | 15300 psi (1075 kg/cm²) |

| Machinability | Poor (cracks or melts) | Excellent (lathe, mill, and file workable) |

| Primary Application | Bonding household and lightweight items | Rebuilding shafts, cylinders, and heavy industrial parts |

| Shrinkage Risk | Yes (due to solvent evaporation) | No shrinkage (precise dimensional stability) |

Specialized Introduction: Klevers 101 Two-Component Adhesive; The Solution for Metal Reconstruction

When expensive industrial parts suffer from corrosion, wear, or cracks, replacing them incurs exorbitant costs. Klevers 101 Paste is a powerful two-component epoxy repair paste that effectively acts as “cold metal.” With its advanced formulation, this product not only bonds parts together but also rebuilds lost metal texture.

This two-component product includes a Base and an Activator, which, upon mixing, transform into a very hard, grey-colored material that is fully machinable.

Strategic Applications of Klevers 101 Two-Component Adhesive

This product goes beyond a simple adhesive and has vital applications in the oil, gas, petrochemical, and power generation industries:

- Repairing Damaged Pump Shafts: Rebuilding worn bearing housing areas.

- Restoring Engine Blocks and Cylinders: Filling cracks and cavities caused by thermal and mechanical stress.

- Rebuilding Hydraulic Rams: Correcting surface scratches on the ram shaft without needing re-plating.

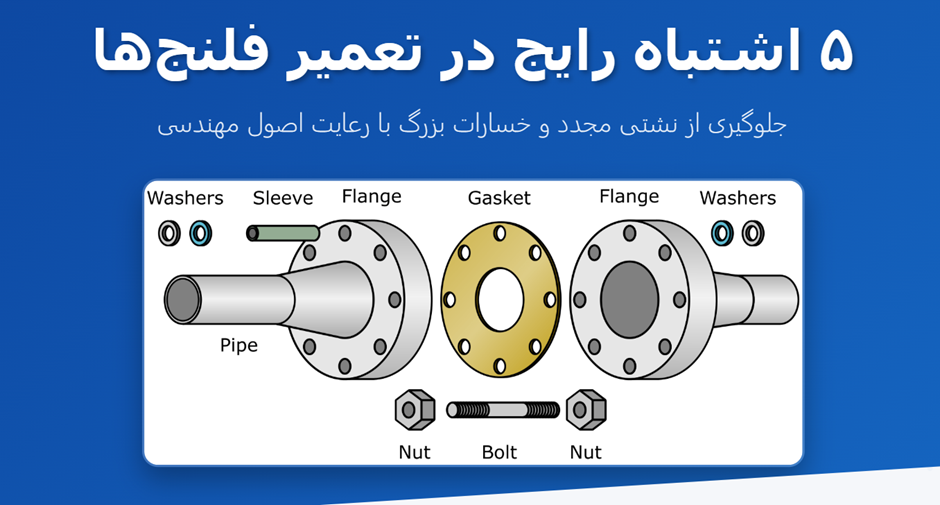

- Sealing Flanges and Pipes: Fixing high-pressure leaks in industrial connections.

- Resurfacing Bearing Seats: Creating a smooth and durable bed for bearing housings.

Technical Data and Engineering Specifications

Maintenance and repair (PM) engineers need precise numbers to select materials. Klevers 101 two-component adhesive complies with the strict standards of Resimac Ltd, UK:

- Compressive Strength: According to ASTM D695, this product withstands an immense pressure of 1075 kg/cm².

- Mixing Ratio:

- By Weight: 5 parts Base to 1 part Activator.

- By Volume: 3 parts Base to 1 part Activator.

- Pot Life: After mixing, you have only 30 minutes (at 20°C) to apply the product.

- Machining Time: The part can be machined after only 2 hours.

- Coverage: One kilogram of the product covers approximately 0.4 m² at a thickness of 1 mm.

Step-by-Step Guide for Using Klevers 101 Two-Component Adhesive

To achieve maximum adhesion and mechanical strength, strict adherence to the following steps is mandatory. Any shortcut in surface preparation can lead to bond failure.

1. Surface Preparation

This is the most critical step. The surface must be completely clean, dry, and free of oil, grease, and rust.

- Using industrial degreasers for cleaning is recommended.

- To create a suitable profile for mechanical keying of the adhesive, sand or blast the surface.

2. Precise Mixing

Unlike common twin-tube adhesives, the mixing ratio for Klevers 101 must be precise.

- Place 3 parts of the base component with 1 part of the activator on a clean surface.

- Mix the two components until a completely uniform, dark grey color is achieved. Tip: Creating a diamond pattern while stirring helps ensure thorough mixing.

3. Application and Shaping

Using a spatula or suitable tool, apply the paste with pressure onto the surface to expel air bubbles and allow the material to penetrate into the surface pores.

4. Curing and Machining

- After 2 hours: Can be filed and lightly machined.

- After 6 hours: Maximum chemical resistance is achieved.

- After 3 days: Final cure and attainment of maximum mechanical properties.

Conclusion and Ordering Klevers 101 Two-Component Adhesive

Using a specialized two-component adhesive like Klevers 101 is a smart solution to reduce production line downtime and save on component replacement costs. With cutting-edge European technology and support from Resimac, this product guarantees the quality of your repairs.

Klevers Aryana, as the specialized authority on insulation and refractory repair materials, guarantees the authenticity and quality of this product. For a free technical consultation regarding the selection of the right adhesive for your project and to receive the complete datasheet, please contact our experts.

Consultation and Purchase:

For direct contact with our technical and sales department, please visit our Contact Us page or call the company numbers.

References and Scientific Sources:

- Handbook of Adhesives and Sealants, Elsevier Science.

- ASTM D1002 – Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens.

- Sciencedirect.com – “High temperature refractory adhesives: Properties and Applications”.

- Klevers.de – Technical Data Sheets.

- Resimac Ltd UK Technical Data Sheets – Metal Repair Systems.

- ASTM D695 – Standard Test Method for Compressive Properties of Rigid Plastics.

- NACE International – Surface Preparation Standards for Adhesive Bonding.