Expansion joints are critical components in industrial system design, providing the necessary flexibility to compensate for dimensional changes caused by thermal fluctuations, vibrations, and mechanical pressures. In strategic industries such as power plants, refineries, petrochemicals, and steel manufacturing, failure to use appropriate types of expansion joints can lead to serious equipment damage, costly repairs, and even production shutdowns.

In this comprehensive encyclopedia, we examine all aspects of expansion joints — from basic physical principles to the latest technologies and industrial applications. This article is designed to provide practical information for engineers, industrial designers, technical specialists, and project managers, enabling them to make informed decisions when selecting, designing, installing, and maintaining expansion joints.

History and Working Principles of Expansion Joints

Thermal Expansion Concept and the Need for Flexible Connections

Thermal expansion is a physical phenomenon where materials increase in volume due to rising temperatures. In industrial equipment that constantly experiences temperature variations, this phenomenon can pose significant challenges. For example, a 100-meter-long steel pipe may elongate by approximately 120 millimeters when the temperature increases by 100°C [1].

If not controlled, this expansion can result in:

- Excessive mechanical stress

- Bending and deformation of pipes and ducts

- Joint failure

- Fluid leakage

- Damaged connected equipment such as pumps and valves

Expansion joints allow materials to freely expand and contract without introducing damaging stresses into the system by creating “flexible points” within the installation.

Historical Background of Expansion Joints

The need to absorb movement caused by temperature changes and pressure has been recognized by engineers for centuries. Early examples of expansion joints were found in water transmission systems of the Roman Empire.

However, the real development of modern expansion joints began during the Industrial Revolution with the emergence of steam pipelines. As temperature and pressure increased in industrial processes in the late 19th and early 20th centuries, the demand for more efficient expansion joints grew significantly.

In the 1930s, the first modern fabric expansion joints were introduced, marking a revolution in the industry. With technological advancements, new materials such as special metals and high-temperature resistant fabrics were developed, further enhancing the performance of expansion joints [2].

Physical Principles Governing Expansion Joints

The function of expansion joints is based on several physical principles:

- Law of Thermal Expansion: The amount of expansion is proportional to the initial length of the material, temperature change, and its coefficient of thermal expansion. ΔL = α × L₀ × ΔT where:

- ΔL = Length change

- α = Coefficient of thermal expansion

- L₀ = Initial length

- ΔT = Temperature change

- Hooke’s Law: Within the elastic range, the stress applied to a material is proportional to the resulting strain.

- Laws of Thermodynamics: Expansion joints must be able to manage heat transfer, pressure, and fluid flow properly.

- Vibration Principles: Expansion joints also play a crucial role in absorbing and damping system vibrations.

Types of Expansion Joints

Expansion joints are divided into three main categories based on their construction materials and applications: metallic, fabric, and rubber. Each type has its own advantages, limitations, and specific uses.

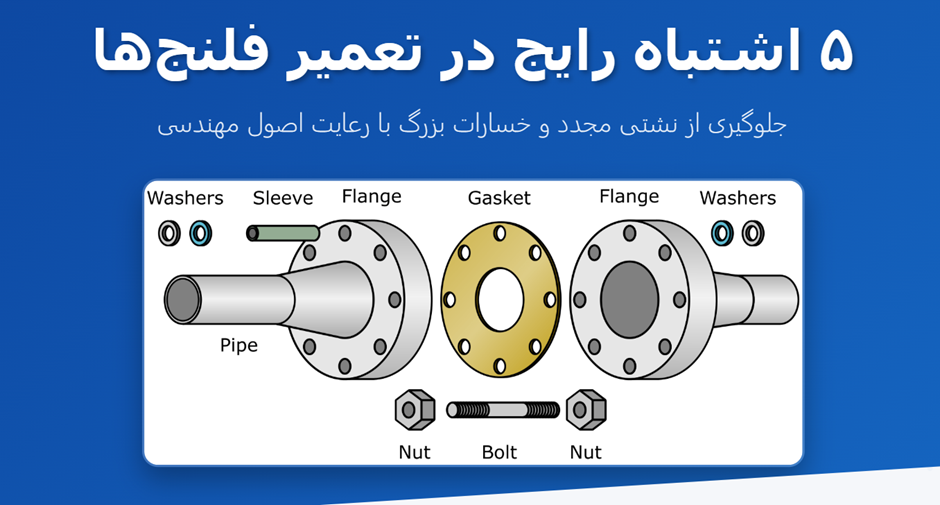

Metallic Expansion Joints

Structure and Components

Metallic expansion joints typically consist of the following components. To learn more about metallic expansion joints, please visit the product page:

- Bellows: The flexible core component usually made of stainless steel, nickel alloys, or titanium.

- Flanges: Used to connect to the piping system.

- Inner Sleeve: Protects the bellows from erosion and corrosion.

- Reinforcing Rings: Increase resistance to internal pressure.

- Limit Rods: Control movement and prevent overextension.

Advantages and Limitations

Advantages:

- Withstands very high temperatures (up to over 1000°C)

- Suitable for high-pressure systems (up to 100 bar and above)

- Good chemical resistance

- Long service life under proper conditions

- Customizable design for special conditions

Limitations:

- Less vibration absorption compared to rubber and fabric types

- Higher cost

- Heavier weight

- Less flexibility

- Requires periodic maintenance

Operational Conditions

Metallic expansion joints are commonly used under the following conditions:

- High-temperature systems (above 400°C)

- High-pressure systems

- Corrosive environments

- Petrochemical, oil, and gas industries

- Thermal power plants (with valve thermal insulation jackets)

- Steel and metal processing industries

According to ASTM F1120 standards, metallic expansion joints must be capable of withstanding at least 10,000 expansion and contraction cycles under design conditions [3].

Fabric Expansion Joints

Structure and Components

Fabric expansion joints are composed of multiple layers of different materials:

- Outer Layer: Typically made of weather-resistant fabrics like PTFE or silicone

- Insulating Layers: Heat-resistant materials such as fiberglass, ceramic fiber, or aerogel. Also see jacketed thermal insulation

- Inner Layer: Resistant to abrasion and corrosion

- Reinforcements: Metallic or carbon fibers to increase strength

- Metal Frame: For attachment to the system

According to Klevers Aryana Company, these types of expansion joints can withstand operating temperatures between 500 to 1000°C and offer excellent resistance to corrosive chemicals [4].

Advantages and Limitations

Advantages:

- Very high flexibility

- Excellent multi-directional motion absorption

- Outstanding vibration and noise absorption

- Lightweight

- Easy and fast installation

- Lower cost compared to metallic types

- Good thermal and acoustic insulation

Limitations:

- Pressure limitation (typically below 0.5 bar)

- Shorter lifespan at high temperatures compared to metallic types

- Periodic inspection and replacement required

- Limited suitability for certain chemical environments

Operational Conditions

Fabric expansion joints have wide application in the following systems:

- Air and gas ducting systems

- Industrial ventilation systems

- Power plant exhaust gas paths

- Cement industry kilns

- Steel industry induction furnaces

- Dust collection systems

- Petrochemical process gas lines

According to technical data published by Frenzelit GmbH, these types of expansion joints are used in hot exhaust gas environments reaching up to 1000°C [5].

Rubber Expansion Joints

Structure and Components

Rubber expansion joints typically consist of the following parts:

- Rubber body: Usually made of EPDM, neoprene, or butyl

- Fabric reinforcements: Polyester, nylon, or Kevlar

- Metal reinforcements: Steel rings or wire reinforcements

- Metal flanges: For system connection

Advantages and Limitations

Advantages:

- Excellent vibration and noise absorption

- High flexibility in multiple directions

- Easy installation

- Good electrical insulation

- Absorbs axial and lateral movements

- Resistant to many chemicals

- Affordable price

Limitations:

- Temperature limitations (usually below 120°C)

- Pressure limitations (up to 16 bar)

- Shorter lifespan compared to metallic types at high temperatures

- Sensitive to UV and ozone exposure

- Degradation in certain chemical environments

Operational Conditions

Rubber expansion joints are widely used in the following applications:

- Cooling water systems

- HVAC systems

- Pumps and compressors

- Water transfer systems

- Fire suppression systems

- Municipal infrastructure

- Food and pharmaceutical industries

Other Types of Expansion Joints

In addition to the three main types, there are other specialized expansion joints:

- PTFE Expansion Joints: Resistant to corrosive chemicals and moderate temperatures

- Hybrid Expansion Joints: A combination of metal and fabric or rubber

- Gimbal Joints: For complex angular movements

- Helical Expansion Joints: For torsional movements

- Flanged Expansion Joints: For easy installation in piping systems

- Accordion Expansion Joints: For large movement absorption

Comprehensive Comparison of Expansion Joint Types

The table below provides a comprehensive comparison of the main expansion joint types:

| Critera | Metallic | Fabric | Rubber |

|---|---|---|---|

| Operating Temperature Range | Over 1000°C | 500–1000°C | Up to 120°C |

| Operating Pressure Range | Up to 100 bar and above | Up to 0.5 bar | Up to 16 bar |

| Flexibility | Low | Very high | High |

| Vibration Absorption | Poor | Excellent | Excellent |

| Chemical Resistance | Excellent (varies by material) | Good | Moderate (varies by material) |

| Service Life | 10–25 years | 2–7 years | 5–10 years |

| Relative Cost | High | Moderate | Low |

| Weight | Heavy | Light | Moderate |

| Installation Complexity | High | Low | Low |

| Thermal Insulation | Poor | Excellent | Good |

| Acoustic Insulation | Poor | Excellent | Good |

| Axial Movement Tolerance | Moderate | Excellent | Good |

| Lateral Movement Tolerance | Moderate | Excellent | Good |

| Angular Movement Tolerance | Limited | Excellent | Good |

| Main Application | High pressure and temperature systems | Hot gas duct systems | Water and medium pressure systems |

Source: Combined technical data from sources [3], [4], and [5]

Applications of Expansion Joints in Various Industries

Expansion joints are used across a broad range of industries. Below is a detailed review of their applications in various sectors:

Power Generation Industry

In the power generation industry, expansion joints play a vital role in various sections:

- Steam and gas turbines:

- Connection between turbine and condenser

- Exhaust gas systems

- High temperature and pressure steam piping

- Boilers:

- Connection between boiler and superheater

- Feedwater systems

- Steam transfer lines

- Condensers:

- Inlet and outlet connections

- Cooling water systems

- Gas duct systems:

- Hot exhaust gas paths

- Emission control systems

In thermal power plants, due to high operating temperatures (sometimes up to 600°C) and frequent start-stop cycles, using suitable expansion joints is essential to prevent equipment damage. In this industry, a combination of metallic expansion joints (for high-pressure steam lines) and fabric expansion joints (for gas ducts) is typically used [6].

Oil, Gas, and Petrochemical Industries

In the oil, gas, and petrochemical industries, expansion joints are used in the following areas:

- Refineries:

- Distillation columns

- Process furnaces

- Heat exchangers

- Pipeline transportation of petroleum products

- Petrochemical complexes:

- Chemical reactors

- Steam crackers

- Refrigeration systems

- Process gas pipelines

- Offshore facilities:

- Pumping systems

- Subsea transfer lines

- Drilling platforms

In these industries, due to the presence of corrosive chemicals, high pressures, and strict safety requirements, it is essential to use high-quality expansion joints compliant with international standards.

Klevers Aryana provides fabric and metallic expansion joints that can withstand corrosive environments and high temperatures in the petrochemical industry, designed and manufactured according to global standards [7].

Steel Industry

In the steel industry, expansion joints are used in the following sections:

- Furnaces:

- Gas discharge systems

- Ventilation systems

- Hot gas transfer ducts

- Hot and cold rolling mills:

- Cooling water transfer lines

- Hydraulic systems

- Steam systems

- Reverberatory furnaces:

- Reducing gas systems

- Natural gas transfer lines

In this industry, due to extremely high temperatures (sometimes up to 1600°C) and harsh working conditions, high-temperature-resistant metallic and fabric expansion joints are used.

Cement Industry

In the cement industry, expansion joints are used in the following sections:

- Rotary Kilns:

- Inlet and outlet systems

- Raw material feeding systems

- Raw and cement mills:

- Material transfer systems

- Dust collection systems

- Clinker coolers:

- Ventilation systems

- Air transfer ducts

In the cement industry, expansion joints must be resistant to abrasive particles and alkaline environments.

Glass Industry

In the glass industry, expansion joints are used in the following areas:

- Glass melting furnaces:

- Exhaust gas systems

- Raw material feeding systems

- Glass forming equipment:

- Cooling systems

- Thermal systems

- Annealing ovens:

- Temperature control systems

- Hot air transfer ducts

In this industry, due to extreme temperature fluctuations and corrosive environments, expansion joints with high thermal and chemical resistance are used.

Other Applications

In addition to the industries mentioned, expansion joints are also used in:

- Paper and pulp industry:

- Steam boilers

- Drying systems

- Food and pharmaceutical industries:

- Sterile systems

- Product transfer lines

- Large building HVAC systems:

- Air ducts

- Chiller systems

- Marine industry:

- Engine cooling systems

- Exhaust systems

- Urban infrastructure:

- Water transfer systems

- Sewage systems

International Standards for Expansion Joints

There are numerous international standards for the design, manufacture, testing, and installation of expansion joints. Some of the most important include:

ASTM F1120 – Specification for Circular Metallic Expansion Joints

This standard, developed by the American Society for Testing and Materials (ASTM), defines design, manufacturing, and testing specifications for circular metallic expansion joints. According to this standard, metallic expansion joints must withstand at least 10,000 operational cycles under design conditions [3].

ASTM F2934 – Specification for Flexible Metallic Expansion Joints for Marine Service

This standard specifies requirements for metallic expansion joints used in ships and marine installations. Due to the unique conditions of marine environments, this standard sets stricter requirements for corrosion and vibration resistance [8].

EJMA – Metallic Expansion Joint Manufacturers Association Standards

The EJMA provides comprehensive standards for the design, manufacture, and installation of metallic expansion joints. These standards include fatigue life calculation methods, stress analysis, and test requirements.

EN 14772 – European Standard for Fabric Expansion Joints

This European standard outlines design, manufacturing, testing, and installation requirements for fabric expansion joints. It focuses on thermal resistance, chemical resistance, and service life.

ISO 10380 – International Standard for Flexible Metallic Tubes

This international standard defines design, manufacturing, and testing requirements for flexible metallic tubes and related expansion joints.

FSA-PSJ-701 – Fluid Sealing Association Standard for Fabric Expansion Joints

This standard, developed by the Fluid Sealing Association (FSA), defines design, manufacturing, and installation requirements for fabric expansion joints. It particularly focuses on gas duct applications.

API 6D – American Petroleum Institute Standard for Pipeline Valves

This standard, developed by the American Petroleum Institute (API), defines requirements for expansion joints used in oil and gas pipeline systems.

UL 1709 – Fire Test Standard for Protective Materials

Although not specifically for expansion joints, compliance with UL 1709 may be required when expansion joints are used in fire-risk environments. Klevers Aryana offers fire protection insulation meeting the UL1709 standard for integrated solutions in high-risk environments [9].

Engineering Selection Guide for Expansion Joints

Selecting the right expansion joint is an engineering process that must consider multiple parameters.

Key Parameters in Expansion Joint Selection

- Operating Conditions:

- Operating temperature (minimum and maximum)

- Operating pressure (minimum and maximum)

- Type of fluid (gas, liquid, mixture)

- Chemical composition of the fluid

- Presence of abrasive materials

- Movement Requirements:

- Axial movement (tension and compression)

- Lateral movement (offset)

- Angular movement (bend)

- Torsional movement (rotation)

- Vibrations

- Physical Requirements:

- Dimensions (diameter, length)

- Weight

- Available space for installation

- Allowable reaction force

- Thermal and acoustic sealing

- Economic Requirements:

- Initial cost

- Maintenance costs

- Service life

- Availability of spare parts

- Installation and Maintenance Requirements:

- Installation ease

- Accessibility for repair and maintenance

- Special tools needed

- Bolt torque requirements

Engineering Calculations

To accurately select expansion joints, the following engineering calculations should be performed:

Thermal Expansion Calculation:

ΔL = α × L₀ × ΔT

Where:

- ΔL = Length change (mm)

- α = Coefficient of thermal expansion (per °C)

- L₀ = Original length (mm)

- ΔT = Temperature change (°C)

Reaction Force Calculation:

F = k × ΔL

Where:

- F = Reaction force (N)

- k = Spring rate of the expansion joint (N/mm)

- ΔL = Displacement (mm)

- Fatigue Life Calculation: Fatigue life is calculated using S-N curves and related equations. These calculations are complex and typically performed using specialized software.

- Pressure Drop Calculation: Pressure drop in expansion joints is calculated using fluid dynamics equations. This pressure drop must be considered in overall system design.

Selection Recommendations

Based on industrial experience and available standards, the following recommendations are provided for selecting expansion joints:

- For high temperatures (>400°C):

- Metallic expansion joints for high-pressure systems

- Fabric expansion joints for low-pressure and duct applications

- For medium temperatures (120°C to 400°C):

- Metallic expansion joints for high-pressure systems

- Fabric or PTFE expansion joints for medium-to-low pressure systems

- For low temperatures (<120°C):

- Rubber expansion joints for medium and low-pressure systems

- Metallic expansion joints for high-pressure systems

- For Corrosive Environments:

- PTFE expansion joints

- Metallic expansion joints made of corrosion-resistant alloys (such as Hastelloy or titanium)

- For Vibration Absorption:

- Rubber expansion joints

- Fabric expansion joints

- For Limited Space Applications:

- Hybrid expansion joints

- Compact design metallic expansion joints

Installation and Maintenance of Expansion Joints

Correct installation and maintenance of expansion joints are essential to ensure proper operation and long service life.

Installation Steps

- Preparation:

- Inspect for potential damage

- Ensure compatibility with system requirements

- Make sure connection surfaces are clean

- Positioning:

- Install expansion joints at the designated position in the design

- Ensure correct alignment with piping or ducting

- Maintain distance from fixed points and supports

- Connection:

- Use recommended torque for tightening bolts

- Tighten bolts in cross pattern

- Use gaskets and seals as per manufacturer instructions

- Adjustment:

- Set pre-load as per manufacturer guidelines

- Adjust limit rods

- Check joint movement freedom

- Insulation:

- Install thermal insulation as per instruction manual if needed

- Ensure insulation does not restrict joint movement

Safety Notes

- System Depressurization:

- Before installation or repair, the system must be fully depressurized.

- Operating Temperature Compliance:

- In hot systems, the system must be cooled down or protective equipment used.

- Protect Expansion Joints:

- Avoid welding near fabric and rubber expansion joints

- Avoid contact of chemicals with expansion joints

- Proper Load Distribution:

- Avoid placing excessive weight on expansion joints

- Do not use expansion joints as supports

Repair and Maintenance

- Periodic Inspection:

- Regular checks for leaks, cracks, corrosion, or wear

- Check bolt condition and connections

- Verify proper movement and functionality

- Inspection Schedule:

- Metallic expansion joints: every 12 months

- Fabric expansion joints: every 6 months

- Rubber expansion joints: every 6 months

- Maintenance Actions:

- Clean external surfaces

- Retighten loose bolts with proper torque

- Replace seals if needed

- Lubricate moving parts as per manufacturer instructions

- Replacement Criteria:

- Cracks or tears

- Irreparable leakage

- Severe corrosion or wear

- Permanent deformation

Case Studies on Different Expansion Joints

Case 1: Fabric Expansion Joints in a Thermal Power Plant

An Iranian thermal power plant faced hot gas leakage from boiler exhaust ducts. Analysis showed that installed metallic expansion joints could not absorb angular movements caused by thermal expansion.

Solution: Klevers Aryana fabric expansion joints capable of withstanding up to 900°C and offering high flexibility were installed.

Result: Gas leakage was completely resolved and maintenance costs reduced by 40%. The power plant’s energy consumption also improved due to reduced heat loss.

Case 2: Vibration Issue in Refinery Pumping System

An oil refinery experienced severe vibration issues in the pumping system, leading to recurring leaks and failures.

Solution: High vibration-absorbing rubber expansion joints were installed at pump inlet and outlet

Result: Vibrations were significantly reduced, increasing pump and joint service life. Maintenance costs dropped by 60%.

Case 3: Thermal Expansion Issue in High-Temperature Steam Line

A petrochemical complex faced excessive mechanical stress in a high-temperature steam line at 540°C and 90 bar pressure.

Solution: Special multi-layer metallic expansion joints were installed to absorb axial and lateral movements

Result: Mechanical stress was reduced below allowable limits, improving system safety. The service life of the piping system increased by 50%.

Future Trends in Expansion Joint Technology

The expansion joint industry is constantly evolving, with innovations being developed to improve performance, extend service life, and reduce costs.

Recent Innovations

- Advanced Materials:

- Super-alloys with higher thermal and corrosion resistance

- Advanced composites for fabric expansion joints

- Nanomaterials for improved mechanical and thermal properties

- Advanced Design:

- Finite element analysis (FEA) for optimized design

- Multi-axis designs for simultaneous movement absorption

- Low-friction designs to reduce reaction forces

- Smart Monitoring Systems:

- Integration of temperature and pressure sensors

- Online status monitoring systems

- Predictive warning systems for timely replacement

Future Trends

- IoT Integration:

- Smart expansion joints with wireless communication

- Real-time data analysis for life prediction

- Integrated industrial asset management

- Sustainability and Environmental Protection:

- Development of environmentally friendly materials

- Design for recyclability

- Energy efficiency and greenhouse gas reduction

- Additive Manufacturing (3D Printing):

- 3D printing of complex metallic expansion joints

- Precise customization for specific applications

- Reduced production time and costs

- Integrated Solutions:

- Combining thermal and acoustic insulation with expansion joints

- Integrated vibration control systems

- Multifunctional solutions to reduce part count

Klevers Aryana Expansion Joint Products

Klevers Aryana, as one of the pioneers in insulation and flexible connection systems in Iran, offers a wide range of expansion joints for various industrial applications.

Klevers Aryana Expansion Joint Types

- Fabric Expansion Joints:

- Designed for temperatures up to 1000°C

- Resistant to chemicals and corrosive environments

- Ideal for gas ducts and industrial ventilation systems

- Excellent vibration and noise absorption

- Metallic Expansion Joints:

- Designed for high-pressure and high-temperature applications

- Made from stainless steel and corrosion-resistant alloys

- Suitable for steam and process fluid pipelines

- Able to absorb axial, lateral, and angular movements

- Rubber Expansion Joints:

- Designed for multidirectional vibration absorption

- Suitable for water and medium-temperature fluid systems

- Electrical insulation capability

- Easy installation and low-cost maintenance

Competitive Advantages

With over 20 years of experience in industrial insulation and flexible connectors, Klevers Aryana offers the following competitive advantages:

- Exclusive Representation of Reputable Brands:

- Exclusive representative of Klevers Germany for raw material supply

- Access to state-of-the-art technology

- Comprehensive Services:

- Custom engineering to meet specific customer needs

- Manufacturing with advanced equipment

- Installation by trained professionals

- After-sales and maintenance services

- Superior Quality:

- Use of high-quality European raw materials

- Compliance with international standards

- Rigorous quality control tests

- Extended product life

- Industry Expertise:

- Extensive experience in power, oil, gas, and petrochemical industries

- In-depth understanding of specific needs of various industries

- Custom solutions for special challenges

Services and Support

In addition to manufacturing and supplying expansion joints, Klevers Aryana offers the following comprehensive services:

- Technical Consultation:

- Selection of the appropriate expansion joint type

- Engineering calculations and design

- Optimization of existing systems

- Installation and Commissioning Services:

- Installation by trained professionals

- Supervision by experienced supervisors

- Customer staff training

- After-Sales Services:

- Periodic inspections

- Repair and maintenance

- Spare parts supply

- Technical Support:

- Answering technical questions

- Resolving potential issues

- Providing optimization guidance

For more information about Klevers Aryana products and services, call 021-91305505 or visit the official website.

Conclusion and Summary

Expansion joints are critical components in modern industrial systems, playing a key role in increasing safety, improving performance, and reducing maintenance costs. Proper selection, installation, and maintenance require specialized knowledge and experience.

In this article, we reviewed expansion joint types, working principles, applications, standards, selection guides, installation, maintenance, and future trends. We also introduced Klevers Aryana’s products and services in this field.

As technology advances and industrial processes become more complex, the importance of expansion joints continues to grow. Collaborating with experts and reputable companies like Klevers Aryana ensures optimal selection and use of these critical components.

References and Citations

[1] ASME B31.1, “Power Piping,” American Society of Mechanical Engineers, 2020.

[2] Frenzelit GmbH, “Fabric and Non-metallic Expansion Joints,” 2024. [Online]. Available: https://www.frenzelit.com/us/products/expansion-joints/fabric-and-non-metallic-expansion-joints

[3] ASTM International, “ASTM F1120-87 Standard Specification for Circular Metallic Bellows Type Expansion Joints,” 2015.

[4] Klevers Aryana, “Expansion Joints (Flexible Connectors),” 2024. [Online]. Available: https://klevers-aryana.com/en/products/expansion-joints/

[5] Metraflex, “ASTM F-1120 vs ASTM F-2934 Expansion Joints Compliance,” 2024. [Online]. Available: https://www.metraflex.com/astm-f

[6] A Different Perspective, “Refractory Materials for the Power Generation Industry,” Insulation Outlook Magazine, 2024. [Online]. Available: https://insulation.org/io/articles/a-different-perspective-refractory-materials-for-the-power-generation-industry-2/

[7] MMP Group, “Refractory Materials in the Petrochemical Industry,” 2024. [Online]. Available: https://mmpgroup.co.in/Petrochemical-Industry.html

[8] ASTM International, “ASTM F2934 – Standard Specification for Metallic Bellows Expansion Joints in Piping Applications,” 2018.

[9] UL Solutions, “Best Practice Guide for Passive Fire Protection for Structural Steelwork,” 2019. [Online]. Available: https://www.ul.com/sites/g/files/qbfpbp251/files/2019-04/Best-Practice-Guide-for-Passive-Fire-Protection-for-Structural-Steelwork.pdf