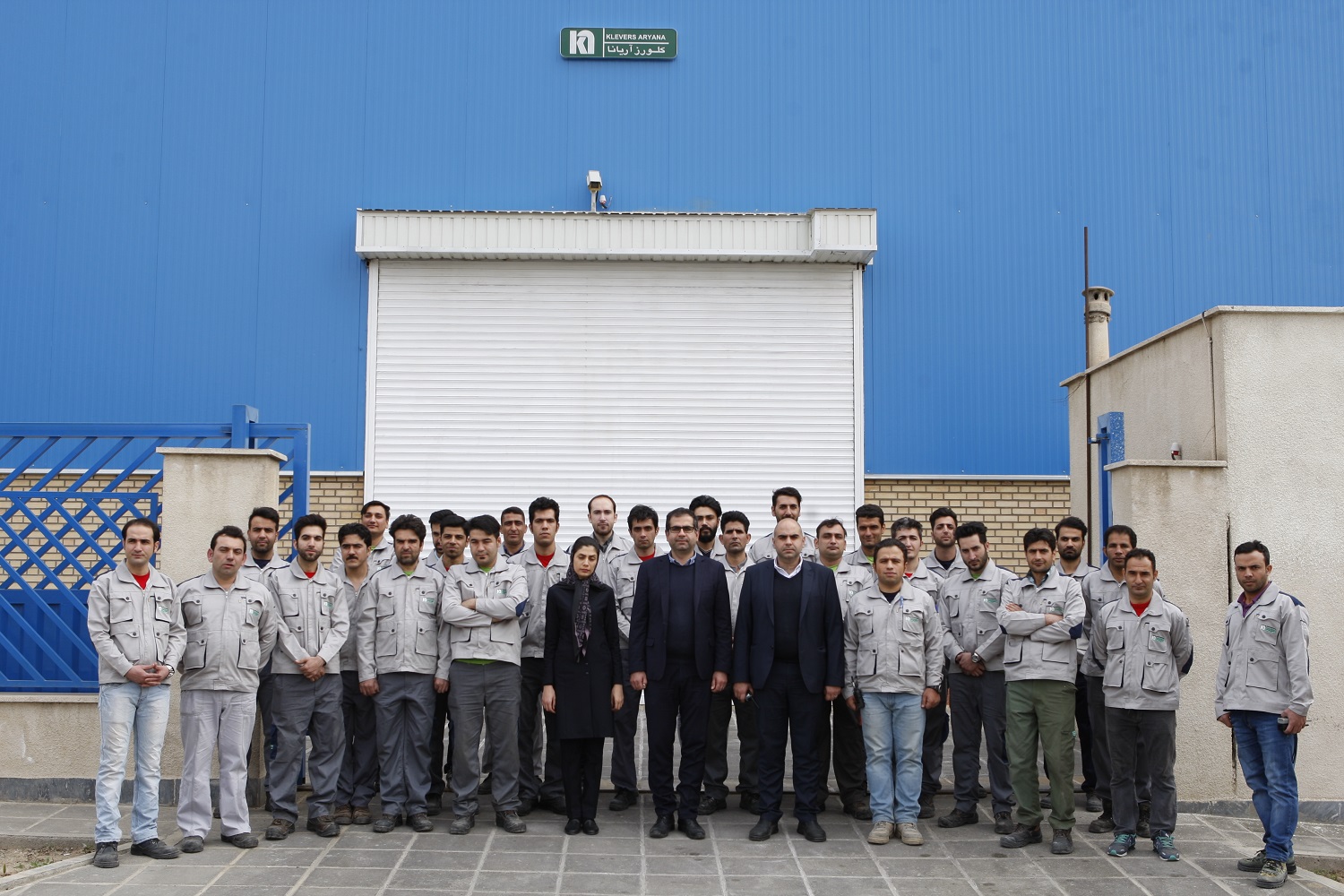

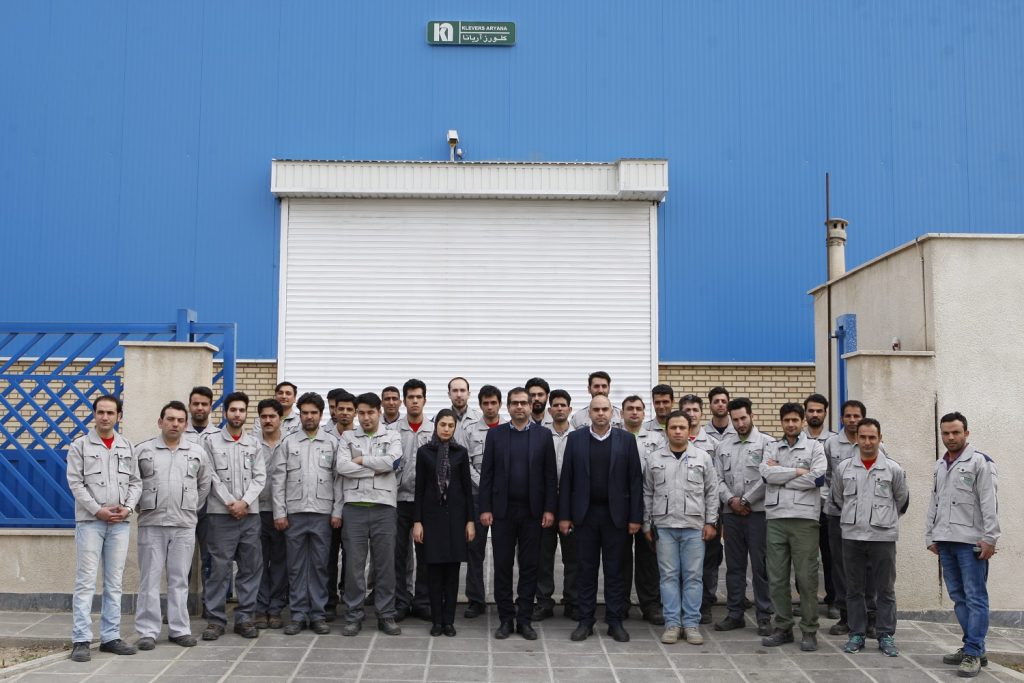

In the world of heavy industries such as power plants, petrochemicals, oil and gas, steel, and marine, choosing a reputable supplier for refractory and high-temperature materials and solutions can mean the difference between success and failure. “Why Klevers Aryana?” This is a question many professionals in various industries ask when looking for a reliable partner for jacket thermal insulation, expansion joints, and fire protection. With over two decades of experience, Klevers Aryana is not just a manufacturer but a comprehensive provider of engineered solutions for high-temperature and corrosion challenges. In this comprehensive article, we will explore the reasons for choosing Klevers Aryana, from its history and services to its innovative products and commitment to standards.

The History of Klevers Aryana: From Inception to Market Leadership

Klevers Aryana began its operations in 2001, focusing on the design, engineering, supply, manufacturing, and installation of flexible thermal industrial insulation and related equipment for power and industrial sectors. The company quickly became a well-known name in Iran’s power, oil, gas, and petrochemical industries. In 2006, to enhance after-sales services, a factory was established in the Hashtgerd Industrial Town. By transferring state-of-the-art technical knowledge and using advanced insulation materials, it enabled the provision of superior services to various industries.

This history demonstrates a long-term commitment to quality and innovation. Klevers Aryana has distinguished itself from competitors by receiving numerous accolades from various associations and institutions. For example, the multiple certifications in the Approvals section of the company’s website are a testament to this claim. This growth trajectory has made Klevers Aryana an ideal partner for large-scale projects that require sustainable solutions.

Klevers Aryana’s Comprehensive Services: From Design to Continuous Support

One of the main reasons for choosing Klevers Aryana is the diversity and quality of its services. The company not only manufactures products but also accompanies its clients through all stages of a project. The main services include:

Engineering and Design

Klevers Aryana’s experienced team of engineers uses specialized software for 3D design and modeling. These services include energy analysis and project efficiency calculations, which help in providing optimal solutions for reducing energy consumption. For more information, visit the Engineering Services page.

Production and Manufacturing

Using up-to-date software and CNC machinery, products are manufactured with high precision. This section ensures that products are transformed from 3D models into reality with superior quality. See the details on the Production Services page.

Installation and Execution

A trained execution team, under the supervision of German and Italian specialists, provides installation and supervision services for domestic and international projects. This ensures a flawless installation. Related link: Installation Services.

Sales and After-Sales Services

After the sale, a specialized team conducts periodic inspections using equipment such as thermographic cameras to measure insulation quality and provide technical reports. These services extend the lifespan of the products. Read more at After-Sales Services.

Research and Development

The R&D department at Klevers Aryana, with its experienced specialists, is always searching for new technologies to align products with global standards. Link: Research and Development.

Trade and Procurement

With extensive connections, high-quality materials are procured in the shortest possible time. Details at Trade Services.

These comprehensive services make Klevers Aryana a top choice, where customers not only buy a product but find a long-term partner.

Klevers Aryana Products: Innovation in Insulation and Protection

Klevers Aryana’s products cover a wide range of industrial needs, from thermal insulation to expansion joints and passive fire protection. All products are made with high-quality European materials.

Jacket Thermal Insulation

These products include various types of insulation covers for pipes, valves, and equipment. Types include:

- Pillow Type: Flexible for complex surfaces.

- Cladding Type: For extra protection in harsh environments.

- Thermal Valve Insulation: Specifically for high-temperature valves.

These jackets conserve energy and enhance safety. For details, visit Jacket Thermal Insulation and subpages like Pillow Type.

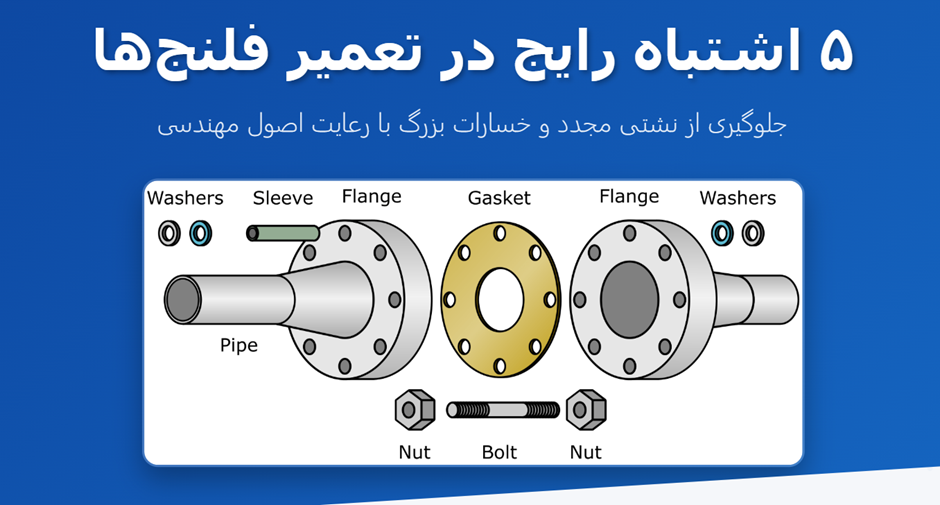

Expansion Joints

Joints are essential for absorbing thermal expansion in piping systems. Types:

- Metallic: Resistant to high pressure, compliant with EJMA standards.

- Fabric: For chemical environments.

- Elastic: For vibrations.

Links: Metallic Joints, Fabric, Elastic. Related article: Metallic Expansion Joints.

Passive Fire Protection (PFP)

These systems are designed to protect structures from hydrocarbon fires, in compliance with the UL 1709 standard. Link: Passive Fire Protection. Article: PFP Insulators.

Fireproof Workwear and Safety Equipment

Simple or fireproof clothing, welding blankets, and fire blankets for worker safety. Links: Workwear, Welding Blanket, Fire Blanket.

Combo Bag and Spring Joints

Combo bags for material transport, spring joints for absorbing vibrations. Link: Combo Bag, Article Combo Bag.

Materials and Coatings

Fireproof fabrics, insulating materials, and corrosion repair coatings like Klevers Paste 101. Links: Fabrics, Insulating Materials, Corrosion Coatings, Article Resimac Coatings.

These products, with a focus on quality and industrial applications, set Klevers Aryana apart.

Advantages and Differentiators of Klevers Aryana

Why Klevers Aryana? The advantages include:

- Quality of Materials: Use of European materials with high standards, such as ASTM C1696 for thermal insulation.

- Reliable After-Sales Service: Periodic inspections and energy analysis.

- Expert Team: Trained engineers and a commitment to customer-centricity.

- Accolades: Numerous certifications, link to Values.

- Innovation: Keeping pace with global technologies in R&D.

Comparison with traditional methods: Klevers Aryana jackets are easier to install and have a longer lifespan than traditional insulation. Related article: Jacket vs. Traditional Insulation.

Standards and Commitment to Quality

Klevers Aryana manufactures its products based on international standards such as ASTM for thermal insulation (e.g., ASTM C518 for thermal conductivity), EJMA for expansion joints, and UL 1709 for PFP. These standards guarantee safety and efficiency. For example, in the marine industry, corrosion coatings comply with ISO 12944.

External links: EJMA Standard, UL 1709, ASTM C1696.

Case Studies: Success in Real Industries

In a power plant, the use of Klevers Aryana thermal jackets resulted in a 20% energy saving, similar to studies by Aspen Aerogels. Website article: Jackets in Power Plants.

In the petrochemical industry, metallic joints prevented pipe failures, based on the EJMA standard. Article: Fabric Expansion Joints.

PFP on an oil rig provided 2-hour protection in a hydrocarbon fire, compliant with UL standards. Article: Fireproof Protection.

Corrosion coatings in the marine industry doubled the lifespan of equipment, based on ISO standards. Article: Metal Corrosion.

These cases demonstrate real-world performance.

Why Klevers Aryana?

Klevers Aryana offers a unique experience to its customers by focusing on standardizing production and maintaining a full commitment to them. A dedication to customer-centricity and exceptional staff promise a bright future.

Conclusion: The Smart Choice for Industries

“Why Klevers Aryana?” Because of its combination of experience, quality, comprehensive services, and commitment to standards. This company not only provides products but also solutions for the real challenges of industries.

About Klevers Aryana

Klevers Aryana specializes in manufacturing thermal insulation, expansion joints, passive fire protection, fireproof clothing, and corrosion repair coatings. Services include engineering, production, installation, and after-sales support. For consultation and purchase, visit our Contact Us page.

References

- ASTM International. (2020). Standard Guide for Industrial Thermal Insulation Systems. ASTM C1696-20. Link.

- Expansion Joint Manufacturers Association. (2023). EJMA Standards. Link.

- UL Solutions. (2022). Testing and Certification of Steelwork Fire Protection. Link.

- ISO. (2018). Paints and varnishes — Corrosion protection of steel structures by protective paint systems. ISO 12944. Link.

- Johns Manville. (2023). Insulation for Power Plants. Link.

- Aspen Aerogels. (2021). High Performance Insulation for Power Generation. Link.

- Belzona. (2022). How to repair pitting corrosion. Link.

- Hempel. (2020). Hydrocarbon passive fire protection. Link.

- Mid-Mountain Materials. (2021). Why Use Thermal Insulation in Hydroelectric Plants? Link.

- Insulation Outlook. (2017). Insulation and Lagging in Power Plants. Link.